The MTRS mechanical splice range has been developed to overcome many of the issues affecting poor jointing of bare overhead conductors with either compression, helical or spring type splices.

Compression, helical and spring-loaded ‘automatic’ type splices all suffer from well-known problems that can compromise their long term performance and reliability.

Life-threatening injuries and the risk of serious property damage caused by mid-span splice failures in the United States has forced network owners to search for a better and more reliable splicing solution to avoid expensive litigation.

Customer Demand Drives Innovation

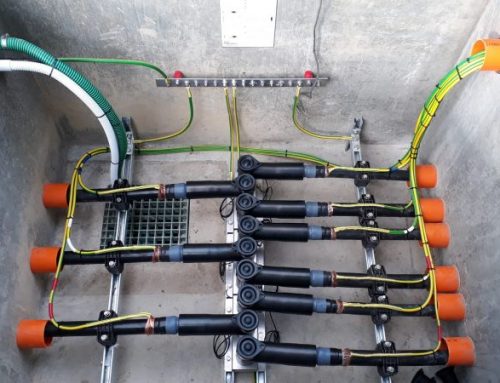

In 2010, several network owners in the USA approached Sicame Australia to develop a new splice, which might employ the mechanical shear-head connection technology that was being successfully employed in the Piranha™ series of underground water-proof connectors, to address the reliability issues inherent with the present-day overhead splices.

The Brief

- Each new splice in the range needed to suit a range of conductor sizes and types, new and old.

- The new splice needed to meet, and preferably exceed, the existing electrical and mechanical performance standards.

- Installation of the splice should not require any special preparation of the conductor, like scratch-brushing.

- Once installed, the splice should not have any protrusions that may scratch or damage slide-on covers.

- The installation of the splice should be easy, and help reduce installer error and any consequences arising from these errors.

- No specialist and expensive installation tooling should be required, and the cost of ongoing equipment maintenance should be minimised.

How does it work?

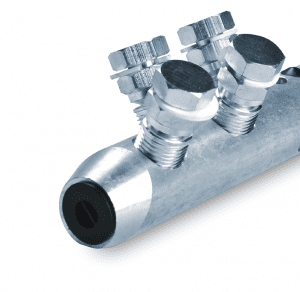

High-torque, shear-head bolts apply pressure points on the conductor via an internal pressure plate in a unique wave-like pattern along its length, thus ensuring superior and reliable mechanical and electrical performance.

Features & Benefits

- Only 4 different splices required to cover conductors from 6 to 25mm OD

- Shear-head bolts for torque control

- Suitable for full and non-tension applications on AAC, AAAC, ACAR and ACSR

- Tested to AS/NZS 1154.1, ANSI C119.1 and IEC61284

- Each end of each splice will suit a wide range of conductors – new and old

- Vent and drain holes allow self-cleaning of pollutants

Request More Information

Want to find out more?