Proven Power Quality Solutions

Improving power quality through power factor correction and harmonic filtering has become a critical consideration for organisations seeking to reduce power costs and minimise risk to operational processes and infrastructure.

Cuthbert Stewart Limited (CSL) has recently proved the effectiveness of its comprehensive power quality solutions by deploying two 400 Amp Active Harmonic Filters for a customer in the North Island.

These systems were designed and manufactured in CSL’s specialised engineering centre TechLab and incorporate innovative technology from global leader in power quality TDK.

TDK’s comprehensive power quality portfolio delivers fit-for-purpose power quality solutions that can be manufactured in TechLab to fit the unique requirements of your operation and budget.

CSL can also help you leverage its system integrator partner network and best-in-class instrumentation from Fluke to measure and analyse simple to complex electrical systems, ensuring that you receive a power factor correction solution that is tailored to your electrical load and the specific infrastructure of your site.

Power Factor Correction

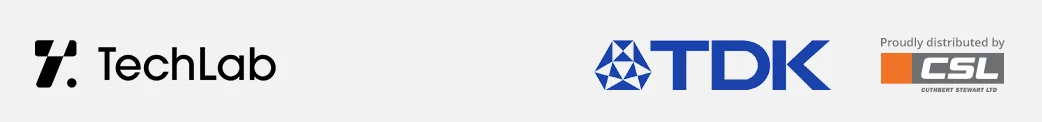

Ideal for reducing the power costs and improving energy efficiency of low and medium voltage networks and industrial sites, CSL’s modular power factor correction solutions consist of capacitors, a contactor, a detuned harmonic reactor, fuses and a fuse switch.

TechLab combines these components into a functional tray that can be easily adapted to fixing in standalone boards or inside main switchboards. CSL offers components, trays or complete PFC panels to improve power factor.

Characteristics

- Capacitor Rated Voltage 525V three phase 50Hz

- Maximum permissible voltage increase; 10% (up to 8 hours daily), 15% (up to 30min daily)

- Ambient Temperature; max 55 ˚C; max mean 24h = 45˚C

- Segregation between capacitors and reactor and contactor

Static VAr Generator

Perfect for industrial sites that seek power cost reduction along with protection from damaging harmonic distortion, CSL’s Static Var Generator uses active components to deliver more efficient energy usage through power factor correction while mitigating the negative impact of power electronics and non-linear loads.

This new approach to power factor correction and load balancing uses faster electronic switching making it an ideal solution for electronic loads which demand faster compensation compared to conventional systems such as capacitor banks.

The Static Var Generator is designed to monitor the current signal and utilise three levels of inverter topology to generate the reactive part of the measured current and dynamically compensate for power factor impacting systems such as: variable speed drives, UPS systems, servers, renewable energy sources, industrial production machinery and welding systems etc.

CSL will produce your Static Var Generator in TechLab, ensuring a compact modular design that delivers efficiency and protection tailored to your operation in a small footprint with simple operation and easy maintenance.

Safety Features

- Overload protection

- Internal short-circuit protection

- Overheating protection

- Overvoltage and undervoltage protection

- Inverter bridge protection

- Fan fault alarm

Active Harmonic Filtering

TDK’s active harmonic filters and power optimisers are the latest innovations in power electronics and CSL deploys this best-in-class technology in its premium power quality solutions – active harmonic filtering.

In addition to eliminating harmonics, this solution actively balances the loads to all three phases, performs dynamic VAR compensation and even delivers some transient compensation – innovative features that avoid line resonance and ensure high performance and reliability.

CSL’s active harmonic filtering solution is a modular system that mitigates the impact of non-linear loads and is tailored to the unique energy usage and infrastructure of each customer site.

The most widely used examples of non-linear loads in our industrial environment power electronics are used in variable speed drives, un-interruptible power supplies and arc devices like arc welders and arc furnaces.

These, TechLab manufactured, systems are designed to be installed in parallel to the polluting loads, analyse the line current and its associated harmonics, then generates a compensation current which neutralises the harmonic currents and deliver an, overall, cleaner and less costly power network.

Active harmonic filtering is ideal for any organisation that wishes to minimise the power-cost of operating, use energy to maximum efficiency, introduce flexibility and scalability, minimise maintenance, extend the operating life of its equipment and mitigate the risk of operational interruptions or downtime.

Capabilities

- Eliminate harmonics up to the 50th order

- Offer dynamic VAR compensation

- Balance the load actively to all phases

- Offer high performance

- Have a three-level topology

- Improve power quality and enhance system reliability

- Ensure integrated overload, overvoltage and undervoltage protection

- Ensure low life-cycle costs thanks to a modular concept and low losses

Best-In-Class

Known for delivering innovative solutions using high-quality products from its world-class portfolio of technology brands, CSL’s power quality offering places innovative technology from global leader in power quality, TDK in the hands of New Zealand industry.

For over 90 years, TDK has stood at the forefront of innovation, establishing itself as a global leader in industrial electronics and power quality solutions. With its unmatched expertise in electronic components, energy systems, and data storage, TDK has continuously enhanced the performance and efficiency of industrial systems worldwide.